Fun in the Workshop

November 19, 2010

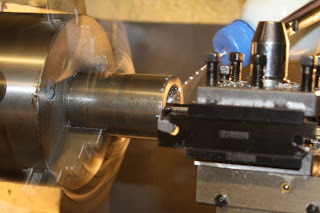

The Duke’s been running pretty well recently, so there’s not much to report on the blog. I’ve been spending my time in the workshop instead, making bits and bobs on the lathe and mill.

Last night, Dr J came round to make a dog to connect his capstan winch to his engine. They cost about £50 each on eBay - even for a copy - so we made one out of a chunk of 45mm bar scrounged from the offcuts bin at a local engineering firm.