EZSnap Motor Mounts

February 28, 2013

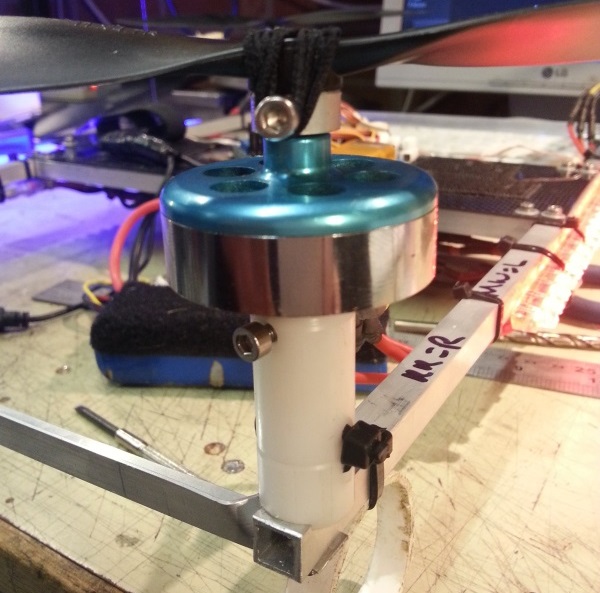

I really liked my old motor mounts for the Quadrotor. I made them on the lathe out of “Engineering Nylon” which costs very little, is easy to machine and can be found on eBay (search for “nylon round bar”). The motor snuggly fits into a 9mm hole and is fixed with two 3mm hex head set screws from either side. Another 3mm set screw goes through the bottom and bolts the mount onto the frame. To stop the torque from the motor spinning the mount I milled a 10mm wide slot into the bottom which fits over the aluminium frame.

I liked them because they are light, look nice and form an integral part of the frame (so no extra cable ties and fixings, just one bolt to do everything). The big problem made itself very apparent when I had a crash on the airbase; the motor hit the ground first and because there was no “give” in the motor mount I bent the arm and broke the motor (detaching one of the magnets).

This would never have happened in the old days - when the factory motor mount was attached to the frame with cable ties. It might have been ugly, but the cable ties would snap long before any other damage could be done.

So, how could I improve my nice looking “purpose built” motor mounts to add a weak point? The answer is in the next picture:

Basically it’s exactly the same design, but with an added cable tie! This time I made the mounts in two parts: a base part which bolts securely to the frame and a motor part which sits on the base and is held down by a cable tie. There’s a little knob on the motor part which sit in the 5.5mm hole in the base part (at the bottom of which the hex-head of the set screw goes). This keeps the two parts locked together as long as the cable tie is in place.

In a crash the cable tie will snap and the motor part will detach - hopefully protecting the motor from damage and protecting the frame in the event of a “motor-first” crash.

Have I tested them yet? Well, no. I’m not going to crash on purpose!