It was raining a little today, so I slobbed on the sofa for a couple of hours before I decided I really should still attempt to get The Duke’s clutch fixed. It’s better to regret something you have done, after all.So, this post is a guide to how I dropped the gearbox, clutch, flywheel and flywheel housing off, ready to to fix the clutch and a suspect crankshaft oil seal. Note that because The Duke is a newer model he has a removable gearbox crossmember, so I didn’t need to take the seat box off.

First job: Get the floor up. Transmission tunnel, gear knobs, floors, and seat bottoms (didn’t want to get them mucky) all got stripped out.

First job: Get the floor up. Transmission tunnel, gear knobs, floors, and seat bottoms (didn’t want to get them mucky) all got stripped out.

Here’s the gear selector at the bottom of the gear stick. I’m sure there’s supposed to be a little ball on the bottom to stop it flapping around. Other than that, eveything looks fine.

Here’s the gear selector at the bottom of the gear stick. I’m sure there’s supposed to be a little ball on the bottom to stop it flapping around. Other than that, eveything looks fine.

Removing the nuts which hold the bell housing onto the flywheel housing. There are quite a few of them, but they all came off nicely in the end.

Before the gearbox can be removed you also need to disconnect the clutch slave cylinder, the handbrake linkage, the front and rear driveshafts and the speedo cable. None of these is easy to remove! I found that the only way to get the rear propshaft off was to unbolt the back first so I could change the angle and get access to the nuts at the gearbox end. The handbrake linkage is made of pure evil.Since I don’t have an angine hoist I slung a rope or two under the gearbox, then used a mixture of jacking, hammering, pulling on ropes, levering and swearing to drop the gearbox and crossmember down in one go. I would not recommend that anyone try it this way. There’s no chance I’m getting it back on without a hoist of some kind!

Removing the nuts which hold the bell housing onto the flywheel housing. There are quite a few of them, but they all came off nicely in the end.

Before the gearbox can be removed you also need to disconnect the clutch slave cylinder, the handbrake linkage, the front and rear driveshafts and the speedo cable. None of these is easy to remove! I found that the only way to get the rear propshaft off was to unbolt the back first so I could change the angle and get access to the nuts at the gearbox end. The handbrake linkage is made of pure evil.Since I don’t have an angine hoist I slung a rope or two under the gearbox, then used a mixture of jacking, hammering, pulling on ropes, levering and swearing to drop the gearbox and crossmember down in one go. I would not recommend that anyone try it this way. There’s no chance I’m getting it back on without a hoist of some kind!

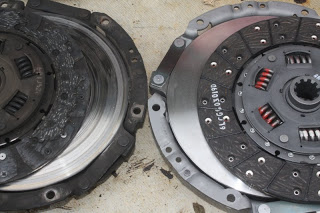

Clutch pressure plate. Lots of dust in there and a nasty oily clag at the bottom which shows that the chaps on the forums were right - the crankshaft oil seal is leaking.

Clutch pressure plate. Lots of dust in there and a nasty oily clag at the bottom which shows that the chaps on the forums were right - the crankshaft oil seal is leaking.

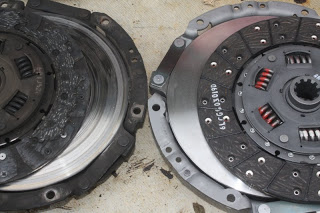

Old and new clutches. The pressure plate side of the clutch is almost totally bald - probably explains my shocking MPG figures! New part is “AP Driveline” who are apparently very good.

Old and new clutches. The pressure plate side of the clutch is almost totally bald - probably explains my shocking MPG figures! New part is “AP Driveline” who are apparently very good.

The last little bit of friction material clings to the old clutch plate.

The last little bit of friction material clings to the old clutch plate.

Next I had to get the flywheel off. The Haynes manual says “undo the bolts and pull off the flywheel”. IIt doesn’t mention that the bolts are tightened hard into something that freely rotates, or that the friction fitting of the flywheel is very hard to overcome! Note the spanner in the picture, which I used to stop the engine turning over while I unscrewed the bolts. I then put the old pressure plate back on and used it to help lever off the flywheel.

Next I had to get the flywheel off. The Haynes manual says “undo the bolts and pull off the flywheel”. IIt doesn’t mention that the bolts are tightened hard into something that freely rotates, or that the friction fitting of the flywheel is very hard to overcome! Note the spanner in the picture, which I used to stop the engine turning over while I unscrewed the bolts. I then put the old pressure plate back on and used it to help lever off the flywheel.

Flywheel off. Next thing to come off was the flywheel housing. Very simple really: six bolts inside the housing and two above. You also need to disconnect the starter motor before the plate will come away.

Flywheel off. Next thing to come off was the flywheel housing. Very simple really: six bolts inside the housing and two above. You also need to disconnect the starter motor before the plate will come away.

Flywheel housing detached. Full of a nasty sludge of clutch dust and leaked engine oil.

Just getting all that to bits took five hours of constant work. I have cut my hands to ribbons, got rust and oil in my eyes and not a single new part has been attached yet! Watch this space for chapter two…

Flywheel housing detached. Full of a nasty sludge of clutch dust and leaked engine oil.

Just getting all that to bits took five hours of constant work. I have cut my hands to ribbons, got rust and oil in my eyes and not a single new part has been attached yet! Watch this space for chapter two…