Britpart Oil Seal Fail

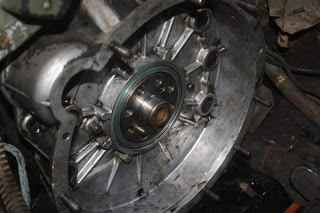

More work on fixing the clutch today, but it all came to nothing. It was a learning experience and a useful test fitting of the flywheel housing, but otherwise a hugely frustrating day!

Obviously the problem was with the low quality of the rubber in the seal, which seemed very stiff compared to the original. The stiffness of the rubber and poor quality of the press-out plastic shaper which allows it to slide over the crank (or not!) is hopefully what sets the cheap Britpart replacement apart from the original part.

I’m going to have to order a new original replacement now - for £30 - and wait for it to arrive. Since I’m away on a cake delivery mission next weekend The Duke is going to be off the road for at least another three weeks. Very depressing!